产品描述

Cooteck 贴片胶采用独特的低温固化技术,不仅解决了热敏感元器件对低温固化的要求,同时也适用于高温无铅波峰焊。根据各种不同的工艺要求研发,Cooteck贴片胶具有极宽的操作窗口,可以满足所有电子厂家的加工应用。

产品特点

◆ 单组分加热固化环氧胶

◆ 更宽的工艺窗口

◆ 适用于高速机器点涂或手动刮涂

◆ 优异的耐热性

◆ 良好的贮存稳定性

◆ 用于波峰焊前表面贴装元器件的粘接

产品规格

|

型号 |

颜色 |

密度 g/cm3 |

粘度

5rpm@25℃,Pa.s |

触变指数 |

Tg

℃ |

固化条件 |

|

COO306 |

红色 |

1.1-1.3 |

500 |

≥6.8 |

≥110 |

60s@ 150℃ |

|

COO316 |

红色 |

1.1-1.3 |

350 |

≥6.5 |

≥110 |

60s@ 150℃ |

|

COO326 |

红色 |

1.4 |

512 |

≥6.8 |

≥45 |

90s@ 100℃ |

|

COO308 |

红色 |

1.1-1.3 |

560 |

≥5 |

≥110 |

60s@ 150℃ |

|

COO318 |

红色 |

1.1-1.3 |

560 |

≥6.5 |

≥110 |

60s@ 150℃ |

其他规格可根据客户需求制作生产。

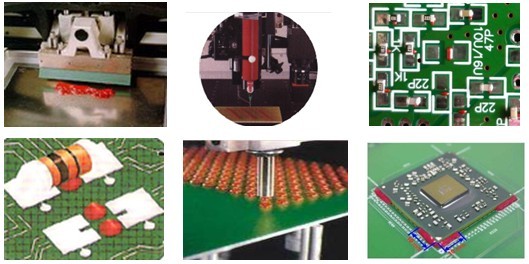

产品应用